XF200L Ultrasonic Anemometer Sensor

The XF200L Ultrasonic Anemometer Sensor is a high-performance, solid-state wind speed and direction sensor designed for professional meteorological, environmental, and industrial monitoring. Using advanced ultrasonic time-of-flight technology, it provides precise wind speed and direction data with rapid response, excellent stability, and no mechanical wear. Its compact weather-resistant structure ensures long-term reliability in harsh outdoor environments, making it ideal for fixed stations, smart agriculture, urban monitoring, and renewable energy applications.

|

Parameter |

Specification |

|---|---|

|

Wind Speed(Range) |

0-40m/s |

|

Wind Speed(Resolution) |

0℃-70℃ |

|

Power Supply |

DC9-24V |

|

Level of Protection |

IP65 |

|

Output |

Rainfall Duration, Rainfall Intensity, Maximum Intensity |

Introduction

The XF200L Ultrasonic Anemometer Sensor is a compact, solid-state ultrasonic anemometer delivering fast, precise wind speed and direction data with high stability and durability for all-weather monitoring.

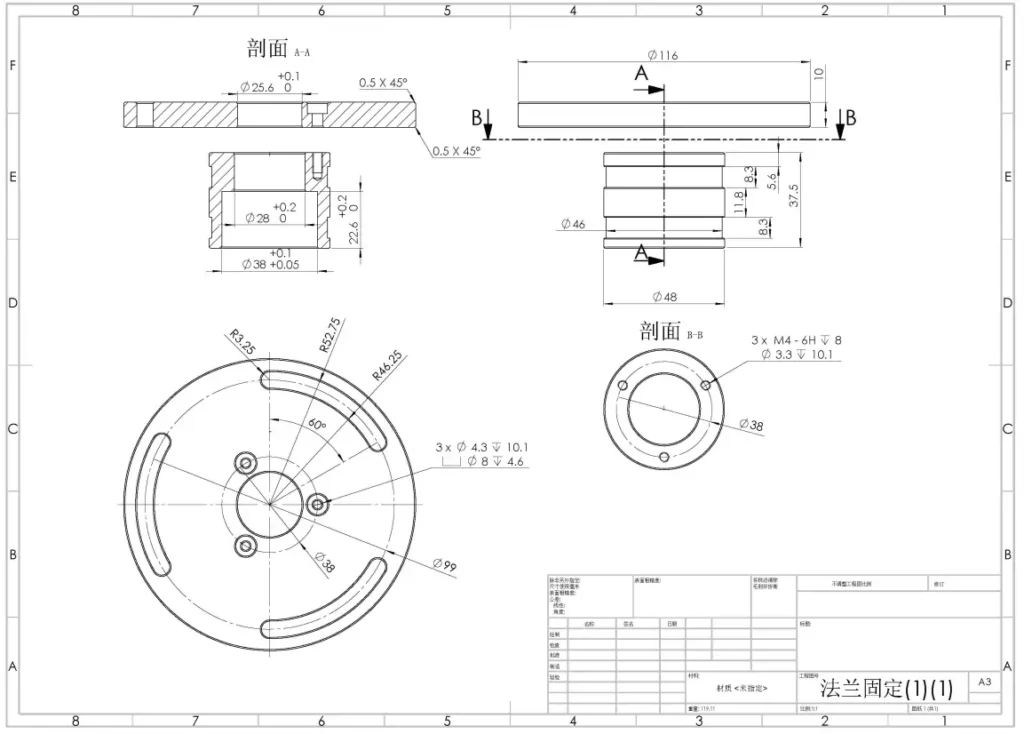

XF200L Ultrasonic Anemometer Sensor Structures

- Ultrasonic Transducer Array:Four or more pairs of transmit/receive units measure wind speed and direction via acoustic time-of-flight differences.

- Streamlined Wind-Resistant Housing:Constructed from weather-resistant materials to minimize airflow interference and ensure long-term stable outdoor operation.

- Integrated Electronic Module:Built-in signal processing, power management, and data output circuits enable high-precision real-time calculations.

- Environmental Protection Structure:Waterproof, dustproof, and corrosion-resistant design for harsh climates and long-term outdoor deployment.

- Mounting Base and Interface Structure:Provides standard mounting interfaces compatible with various brackets for quick installation and maintenance.

- Communication and Output Interfaces:Supports multiple output methods including RS485/RS232 and Modbus for flexible data connectivity.

Details Show

Explore the precision behind the XF200L Ultrasonic Anemometer Sensor: every structural detail is engineered for reliability, durability, and superior wind measurement performance.

ultrasonic anemometer working principle

The XF200L ultrasonic anemometer achieves high-precision wind speed and direction measurement by combining multiple advanced technologies. Its working principle will be explained in detail below.

- Ultrasonic Time of Flight Measurement: Calculates wind speed and direction by measuring the time difference of ultrasonic waves propagating in different directions.

- Bidirectional Propagation Comparison Principle: Ultrasonic waves travel faster with the wind and slower against it; wind speed is obtained by comparing the time difference of bidirectional propagation.

- Triangulation Layout: Sensors typically employ a three- or four-probe structure, calculating two-dimensional or three-dimensional wind fields using multi-directional sound wave propagation data.

- Temperature Compensation Correction: Real-time temperature measurement corrects for changes in sound speed, resulting in more accurate wind speed calculations.

- Solid-State Structure Without Mechanical Parts: Relying on sound waves rather than rotating parts for detection avoids mechanical inertia and delays, enabling rapid response.

- Digital Signal Processing (DSP) Technology: Algorithms filter out interference and noise, improving measurement stability and resistance to environmental interference.

Specifications

Explore the core performance of the XF200L ultrasonic wave sensor: high-precision wind speed and direction measurement, fast 10 Hz sampling, wide temperature tolerance range, and versatile RS485/Modbus output designed for various applications.

Parameters Measuring Range Resolution Accuracy Sampling Frequency

|

Wind Speed

| 0-40m/s | 0.01m/s | ±(0.5+0.05V)m/s | 10HZ |

| Wind Direction | 0-360° | 0.1° | ±5°

(when wind speed <10m/s) | 10HZ |

| Operating Temperature | -30℃—70℃ | |||

| Output | Standard product with RS485 interface, ModbusRTU;

Customized option SDI-12 (additional purchased) | |||

| Maximum Output Frequency | Passive Mode: 1/S Active Mode: 1/min | |||

| Power Supply | DC9-24V | |||

| Protection Level | IP65 | |||

| Cable | 3 meter cable line (Optional: 10 meter cable line available for extra cost ) | |||

| Note | 1. Wind speed and direction: The sensor uses the ultrasonic principle to measure wind speed and direction, and can also output instantaneous wind speed, instantaneous wind direction, average wind speed, average wind direction and other data.

2. XF_PcSoftV1.0: The upper computer reading software developed by Handan Yunnong Intelligent Agricultural Technology CO., LTD. for XF series compact weather station. | |||

Features of Ultrasonic Anemometer Sensor

No mechanical structure design

Fully solid-state ultrasonic measurement ensures wear-free, zero-maintenance operation with long-term stability

High-precision wind speed and direction

Wind speed accuracy: ±(0.5 + 0.05V) m/s; wind direction resolution: 0.1°; for meteorological applications.

Rapid 10 Hz Sampling Rate

Enables high dynamic response, suitable for transient wind fields, wind energy assessment, and similar scenarios.

Robust Weather-Resistant Construction

IP65 protection rating, withstands extreme temperatures (-30°C to 70°C), ideal for long-term outdoor deployment.

Multi-protocol output compatibility

Standard RS485/Modbus RTU with optional SDI-12 for seamless integration into diverse monitoring systems.

Compact lightweight design

Compact, easy to install, and ideal for weather stations, smart agriculture, and environmental monitoring.

applications of Ultrasonic Anemometer Sensor

The XF200L ultrasonic Anemometer Sensor anemometer is a measuring instrument that uses the time difference of ultrasonic waves propagation in the air to measure wind speed and direction. It can be widely used in urban environmental monitoring, wind power generation, meteorological monitoring, bridges and tunnels, marine vessels, and airports, requiring no maintenance or on-site calibration.

Meteorological Monitoring System

Used in automatic weather stations and regional monitoring points to provide precise wind speed and direction data.

UAV Environmental Monitoring

Lightweight design compatible with drones, enabling real-time wind field monitoring to enhance flight safety.

Grid-Based Environmental Monitoring

Supports urban precision monitoring networks by delivering high-resolution wind data.

Agricultural Meteorological Monitoring

Provides critical wind parameters for smart agriculture, enabling farm management and disaster alerts.

Transportation Meteorological Monitoring

Deployed at transportation hubs to ensure real-time wind condition monitoring for road and shipping safety.

Photovoltaic Environmental Monitoring

Monitors wind conditions at power stations to enhance PV operation efficiency and safety.

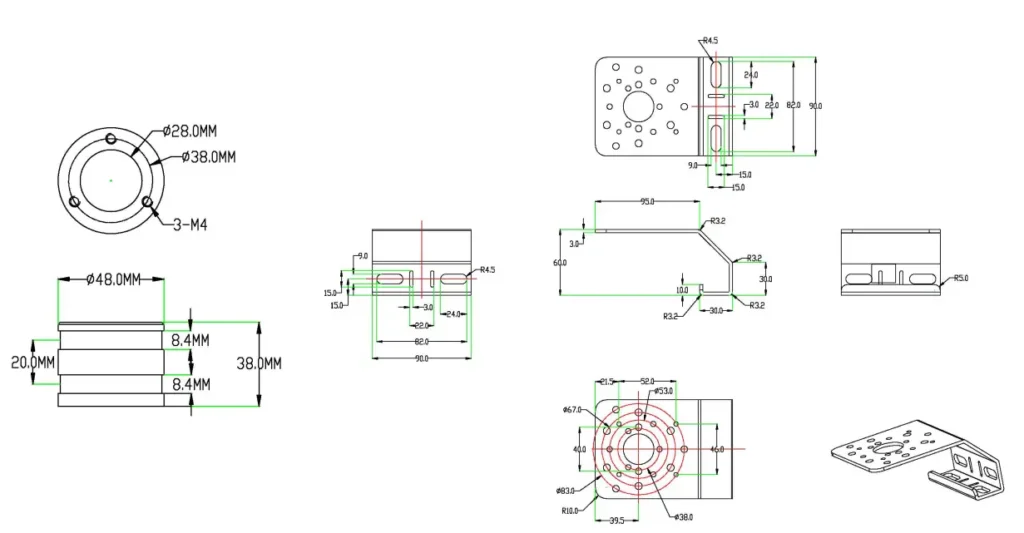

Fixation method

The XF200L Ultrasonic Anemometer Sensor offers two standard mounting options—flange mounting and bent plate mounting—allowing you to choose freely based on your installation environment. This ensures stable operation of the equipment and delivers more accurate wind speed and direction data.

custom ultrasonic Anemometer Sensor

The XF200L ultrasonic wind speed sensor supports multiple customization options (structure, installation, measurement range, protocol, output, etc.). Leveraging our in-house R&D and manufacturing capabilities, we swiftly meet diverse application requirements. Contact our team for a tailored solution.

- Customizable Measurement Range and Accuracy: Wind speed range, resolution, and accuracy grade can be adjusted according to application requirements.

- Customizable Communication Interfaces: Supports customization of protocols and interfaces including RS485, MODBUS, NMEA, TTL, and 4G.

- Customizable Output Signals: Digital output formats or analog outputs (e.g., 0–5V, 4–20mA) can be customized.

- Structure and Mounting Method Customization: Supports various mounting modifications including flange plates and bent plates.

- Cable Specification Customization: Customizable cable length, material, and waterproof connector types.

- Enhanced Exterior Material and Weather Resistance: Offers housing options like ASA, aluminum alloy, and corrosion-resistant treatments for extreme environments.

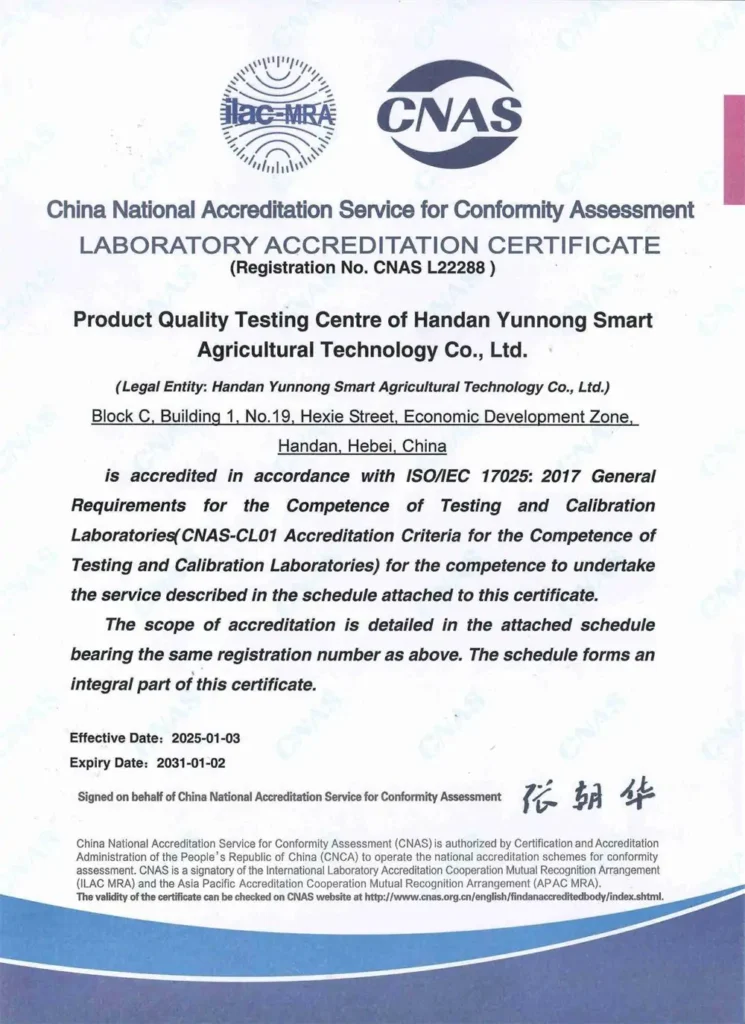

Ultrasonic Anemomete Sensor Manufacturer and Supplier

Yantai Sensor is a modern devices wind sensor anemometer in the R&D and production of ultrasonic anemometers, equipped with an in-house R&D team, modern production lines, and a professional wind tunnel laboratory. Our XF200L Ultrasonic Anemometer Sensor holds CNAS, CE, ISO, and RoHS certifications. Validated through extreme environment testing, it delivers stable and reliable performance for widespread use in meteorology, agriculture, environmental protection, and transportation sectors. We offer flexible customization solutions and system integration services. Contact our expert team for professional support and high-quality products.