Greenhouse Temperature Controller

Greenhouse temperature controllers are the core operational equipment in modern greenhouse environmental control systems. By integrating with sensors for temperature, humidity, CO₂, and other parameters, they automatically regulate vents based on preset conditions, ensuring precise control of indoor climate.

It can prevents excessive heat and humidity, enhances ventilation, reduces the risk of pests and diseases, and allows flexible adjustment of ventilation strategies according to crop growth stages. It minimizes the need for manual intervention, improving overall management efficiency.

|

Parameter |

Specification |

|---|---|

|

Power supply |

DC12V or DC24V |

|

Operation method |

Manual or automatic |

|

Waterproof rating |

IP67 |

|

Contact method |

4G |

|

Single package size |

50X20X20 cm |

Introduct

Greenhouse Temperature Controller are automated devices used for environmental control in greenhouses. They intelligently control the opening and closing of vents based on parameters such as temperature and humidity, improving air circulation and environmental stability within the greenhouse, and reducing manual labor and energy waste.

Structure of Greenhouse Temperature Controller

Wiring Section

- Aviation Connector Section: Default connection to temperature sensor. Optional temperature/humidity sensor. Optional rain/snow sensor.

- Power and Control Section: The controller supports both 12V and 24VDC power supplies. Select the appropriate power supply based on the chosen roller. For example, if using a 12V 50W roller, select a 12V power adapter rated at 60W or higher; if using a 24V 100W roller, select a 24V power adapter rated between 100W and 130W.

Indicator light section

① Power indicator. Remains lit when the controller is powered on.

② Network indicator. Remains lit when the controller is successfully connected to the server; turns off if the connection fails. Flashes when data is being exchanged between the controller and server.

③ Button indicator. Flashes once when a button is pressed and held; remains off by default.

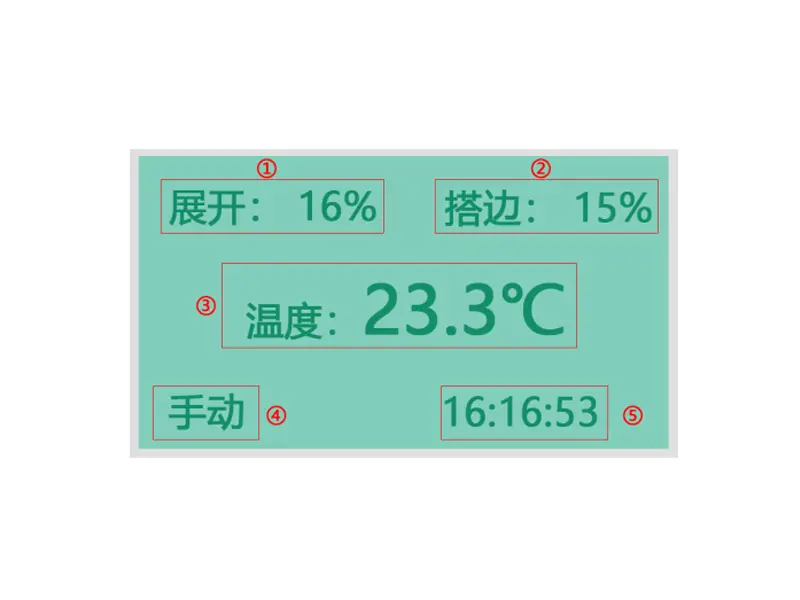

LCD section

① Percentage of vent opening. 0% indicates the vent is fully closed, while 100% indicates the vent is fully open.

② Overlap position. Indicates the current overlap position of the greenhouse, as shown in the figure, where the vent reaches the overlap position at 15% opening.

③ Parameter display. Shows the current greenhouse temperature. If equipped with a temperature and humidity sensor, it cycles through displaying the current greenhouse temperature and humidity every 5 seconds. If the sensor malfunctions, an asteriskis displayed.

④ Operating mode display. Shows the current operating mode, which includes: Manual, 3-stage segmented, 5-stage segmented, 3-stage smart, 5-stage smart, and One-touch dehumidification.

⑤ Time display. Shows the current time (24-hour format).

Details Show

The greenhouse ventilation fan features comprehensive optimizations in structure, materials, and sealing techniques. With an IP67 waterproof rating, the entire unit withstands rain exposure and effectively handles complex greenhouse environments characterized by high humidity, high salinity, and elevated temperatures. Core components are fully protected, ensuring stable and reliable operation suitable for long-term continuous use. The following details illustrate the design advantages of this smart ventilation fan in terms of durability and reliability.

Specifications

To help you gain a more intuitive and comprehensive understanding of the performance and applicable scenarios of greenhouse ventilation fans, the following parameters clearly outline aspects such as structural design, electrical performance, protection rating, and operational capacity. By reviewing these key technical specifications, you can quickly determine whether the product aligns with your current greenhouse scale and environmental requirements, providing a reference basis for subsequent model selection and system integration.

Parameters

| Power supply | DC12V or DC24V | Operation method | Manual or automatic |

| waterproof rating | IP67 | contact method | 4G |

| Single package size | 50X20X20 cm | Single gross weight | 5.000 kg |

Features of Greenhouse Temperature Controller

Waterproof and Dustproof

Features an IP67 waterproof and dustproof design, suitable for rainy conditions and high-humidity, high-salt environments in greenhouses.

Long-Term Stable Operation

Key components are well-protected, suitable for continuous long-term operation with stable performance.

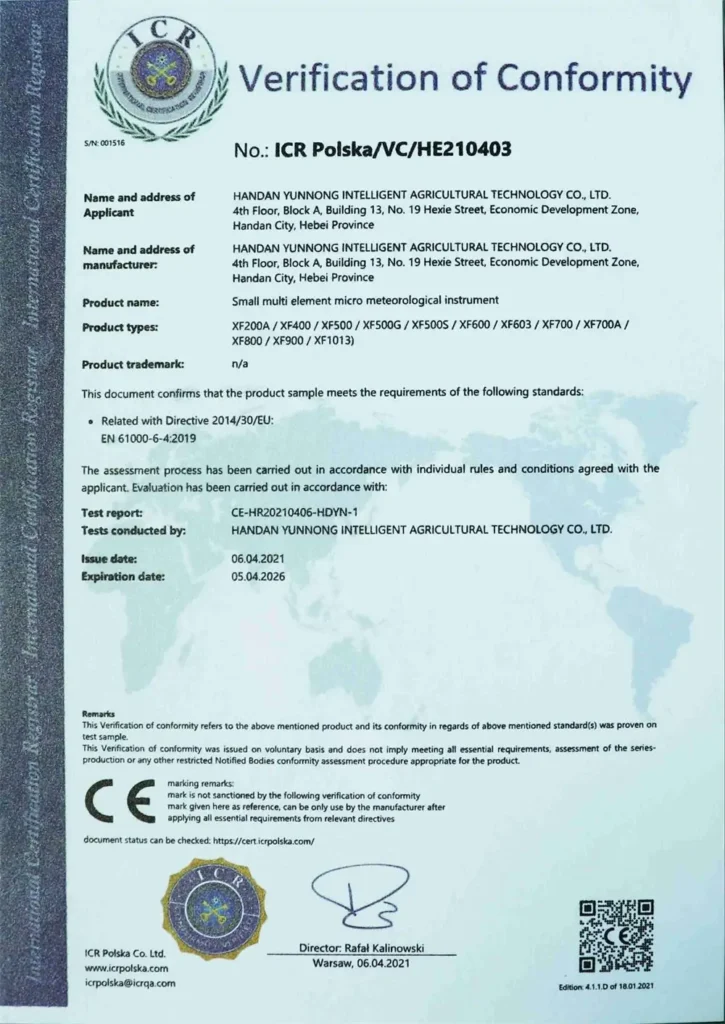

Advanced Communication

Built-in 4G communication module provides stable network connectivity and timely data transmission, reducing wiring complexity.

High Independence

Each ventilation fan acts as an independent terminal, directly connecting to the network without the need for intermediate devices.

Simplified System Structure

Reduces connection points, lowers the risk of system failure, and makes the system more stable and reliable, improving overall reliability.

Flexible and Scalable Deployment

Supports decentralized or centralized installation, facilitating greenhouse expansion and future management.

Functions of Greenhouse Temperature Controller

Greenhouse ventilation fans are widely used in greenhouse environmental control and smart agricultural management. Through automated ventilation and intelligent control, they improve indoor air conditions, reduce disease risks, and enable centralized, visual management, providing stable and efficient environmental support for agricultural production. For more details, please click to view our Smart Agriculture Solutions.

Temperature and Humidity Regulation

Automatically ventilates and controls humidity based on greenhouse environmental changes, maintaining optimal growing conditions for crops.

Disease Prevention

Improves air circulation, reduces high humidity and stuffiness in greenhouses, and lowers the incidence of pests and diseases.

Disaster Early Warning

Integrates with environmental monitoring systems to provide timely alerts for abnormal conditions such as high temperatures and humidity, and executes ventilation accordingly.

Time-Scheduled Ventilation Control

Manages ventilation based on crop growth stages and time-specific requirements, preventing over- or under-ventilation.

Centralized Greenhouse Management

Unifies multiple devices into a single platform for centralized control, ensuring clear visibility and manageability of operational status.

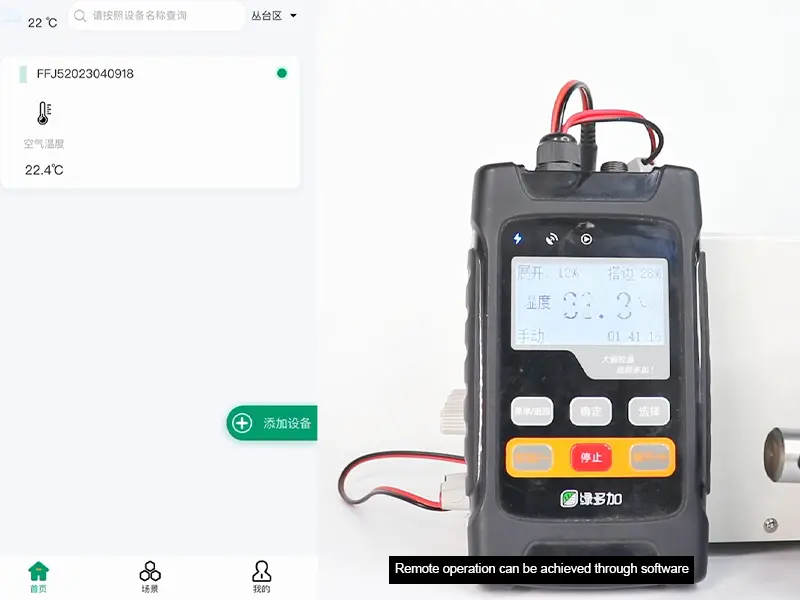

Real-Time Mobile Monitoring

Enables real-time viewing and control via mobile devices, reducing manual inspections and enhancing management efficiency.

Case

The following showcases application cases of smart ventilation fans in greenhouse structures. These real-world installation and operational scenarios provide a clear demonstration of the equipment’s performance in structural design, installation methods, and practical use. Detailed images below will help you better understand the stability, reliability, and application effectiveness of smart ventilation fans in greenhouse environments, serving as a reference for future model selection and solution planning.

custom best greenhouse temperature controller

The best greenhouse temperature controller can be flexibly customized to suit varying cultivation scales, environmental conditions, and management approaches. From structural design and control methods to communication protocols and system integration, these fans adapt to practical application needs, meeting ventilation and intelligent management requirements across diverse greenhouse scenarios.

Customization Options

- Control Method Customization: Supports automatic, manual, and remote control. Operating logic can be programmed based on parameters like temperature and humidity.

- Communication Method Customization: Options include 4G, RS485, and other communication protocols for seamless integration with various monitoring platforms or management systems.

- Power and Thrust Customization: Matches motor power and output thrust to specific vent dimensions and greenhouse structures.

- Customizable Structure and Installation: Supports multiple installation configurations like side vents and roof vents, adapting to various greenhouse types.

- Customizable Protection Rating and Environmental Adaptation: Optimized sealing and protective designs for high-humidity, high-salinity, or high-temperature environments, enhancing durability.

- Customizable System Integration and Functionality Expansion: Interoperates with environmental sensors, weather stations, or agricultural platforms for centralized management and feature expansion.

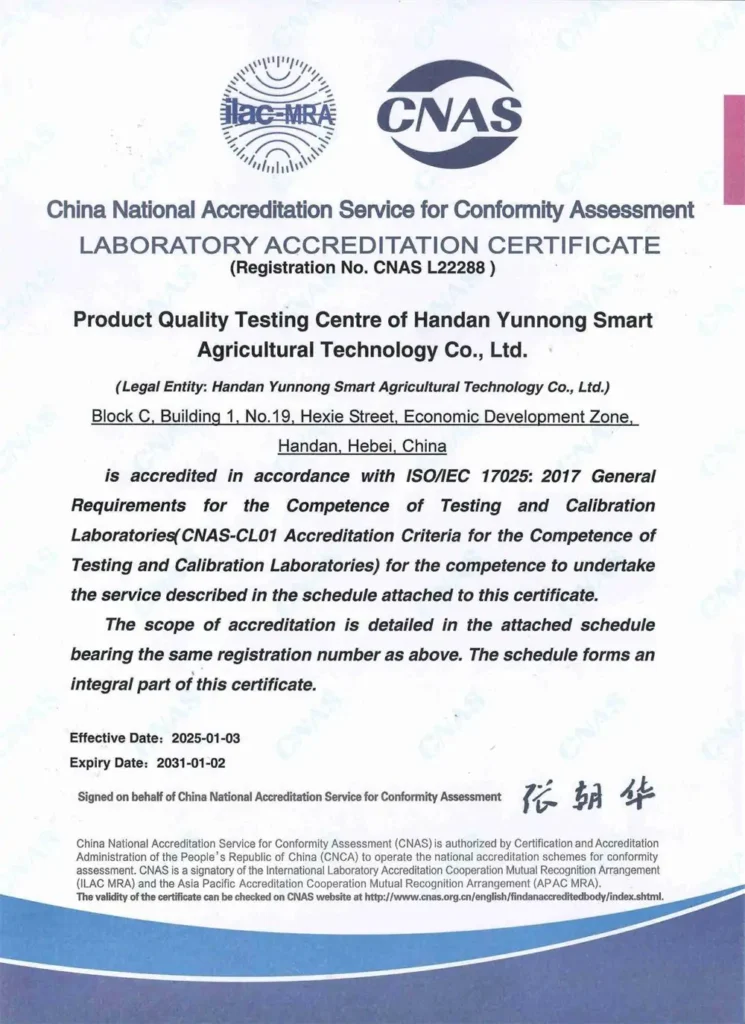

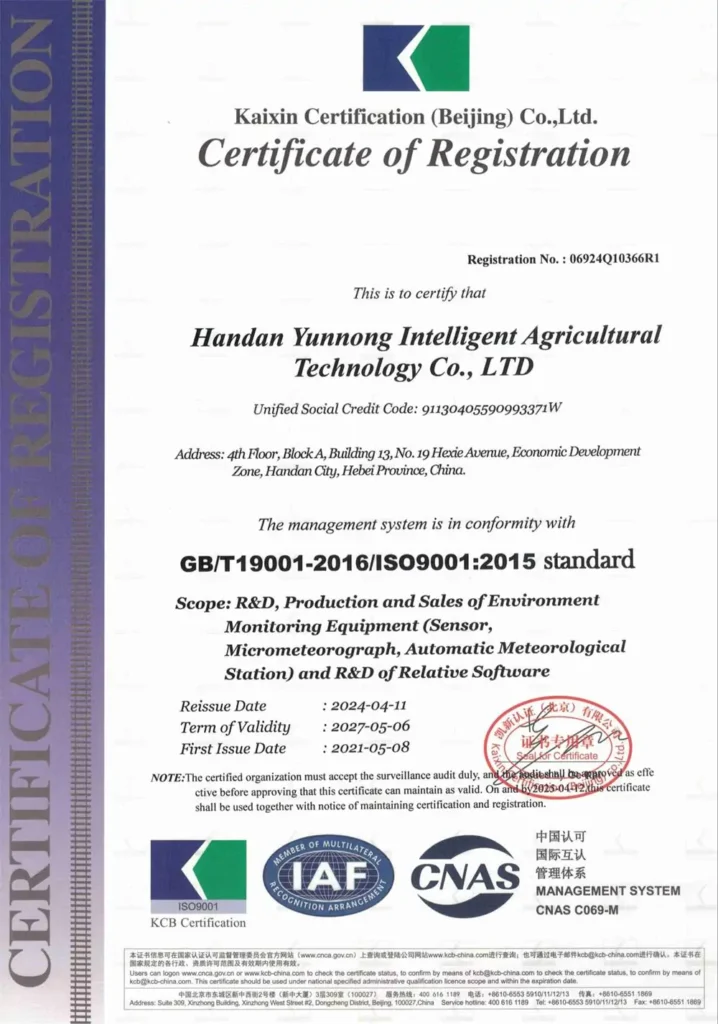

Greenhouse Temperature Controller Manufacturer and Supplier

As a temperature and humidity controller for greenhouse manufacturers and suppliers, we focus on the design and production of reliable control equipment for modern greenhouse management. Backed by an experienced technical team and in-house manufacturing capabilities, we develop temperature control systems that integrate precise sensing, stable control logic, and durable hardware. Based on specific project requirements, we support customized configurations and system integration, delivering flexible solutions that adapt to different greenhouse structures, climates, and management models. Contact our professional team to access high-quality products and comprehensive technical support.